SERVICES

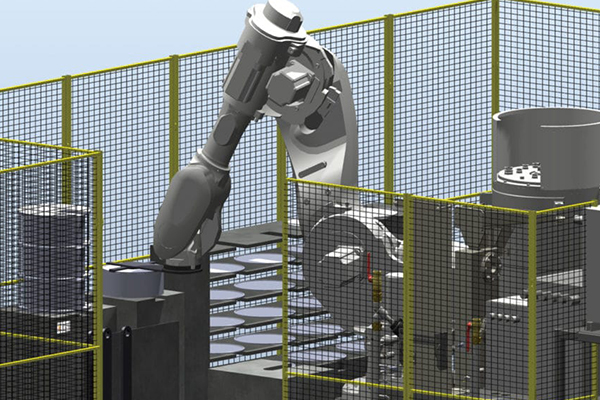

ECM has years of robotics experience in various heat treat fields – from photovoltaic applications (high speed handling) & semiconductor applications (extreme precision) to the automotive industry (high productivity with heavy parts handling). Our robotics & advanced technology expertise can adapt to all heat treatment sectors. Integrate automation into existing lines or for new production projects with a variety of robots and leading edge technologies: polyarticular, parallel & scara, collaborative integration, vision systems & vision tracking.

AGV / AMR

Our AMR and AGV robots, with load capacities of over a ton, enable you to move your loads autonomously to a given destination. Capable of receiving and managing a large amount of information, our robots are able to organize their tasks according to priorities and their remaining autonomy.

ECM Robotics allow you to imagine the layout of your workshop in a different way, to gain a new perspective. We can supply a scalable fleet of AMRs to meet changing needs.

Handling & Transfer Solutions

From the handling of light, fragile loads to heavy automotive-type loads of up to 1000kg. High-precision, high-speed, heavy loads : we meet your production constraints to optimize your logistics flows. Our robots are able to offer handling and transfer solutions adapted to the different needs of our customers :

- Automated magnetic changers

- Adaptation to the geometry of the parts handled

Gripper Development

Gripper development is an integral part of our business. We integrate pneumatic / magnetic / electrical / and vacuum technologies to adapt our automated solutions to your parts and needs.

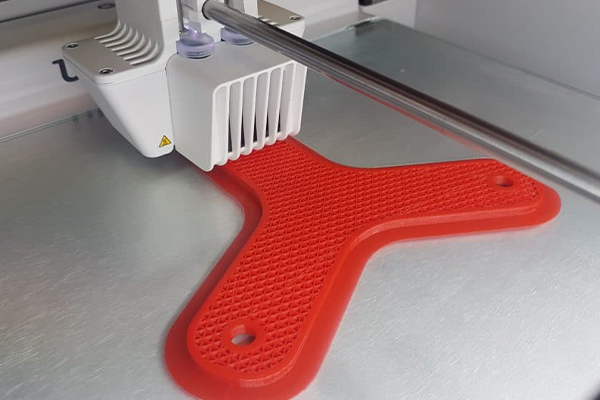

Our 3D printer enables us to rapidly produce prototypes by additive manufacturing, and to be reactive during the design and testing phase of your project.

VIRTUAL REALITY: IMAGINING, CREATING & VISUALIZING

- Used during the planning phase to show the project and illustrate its feasibility

- Helps in dimensioning, conception and in anticipating future developments

- Shows the project in scale 1/1 even before its manufacturing

- Helps in optimizing the conception phase

3D PRINTING: DESIGNING, TESTING & VALIDATING

- An innovative approach to develop and validate grippers

- ECM Robotics has patented its own innovative grippers

- Optimization of the R&D phase: delays & cost reduction compared to aluminum prototypes

- Enhances flexibility and creativity thanks to the test of several concepts

3D SIMULATIONS: SIMULATING TO VALIDATE

- Simulates real loads scenarios to estimate feasibility

- Simulation of real cycle times to 1/10th of a second

- Payload charge simulations allow to predict if a load can be manipulated or not

- Overall validation of implementation concepts and cycles